Experience the blue sea and nature that clear up

with the world's No. 1 Global Echo-scrubber system.

with the world's No. 1 Global Echo-scrubber system.

Global Echo

is confident

is confident

Through marine scrubber solutions, we are doing our best to achieve harmony

with the Earth's nature and protect the marine ecosystem and the future of humanity.

with the Earth's nature and protect the marine ecosystem and the future of humanity.

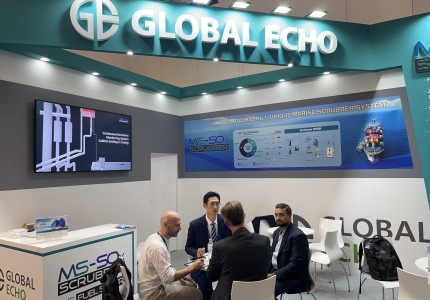

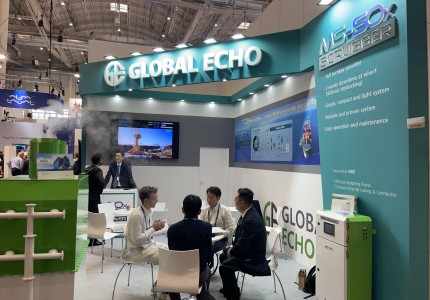

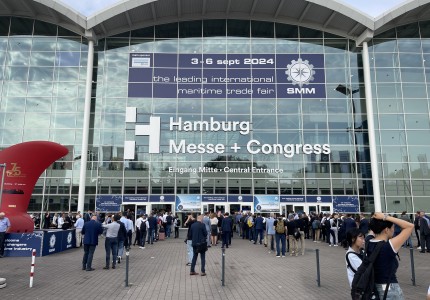

Exhibition

To grow as a global expert in marine

environmental solutions, Global Eco moves forward.

environmental solutions, Global Eco moves forward.

Our technology is constantly

evolving to create a cleaner world

evolving to create a cleaner world

Global Echo is working together to ensure safe navigation

and the environment in the sea, the home of mankind.

and the environment in the sea, the home of mankind.

Join Global Echo and participate in

a sustainable future.

a sustainable future.

We look forward to your valuable

opinions and inquiries.

opinions and inquiries.